Core Options — Divinycell®

Structural Performance

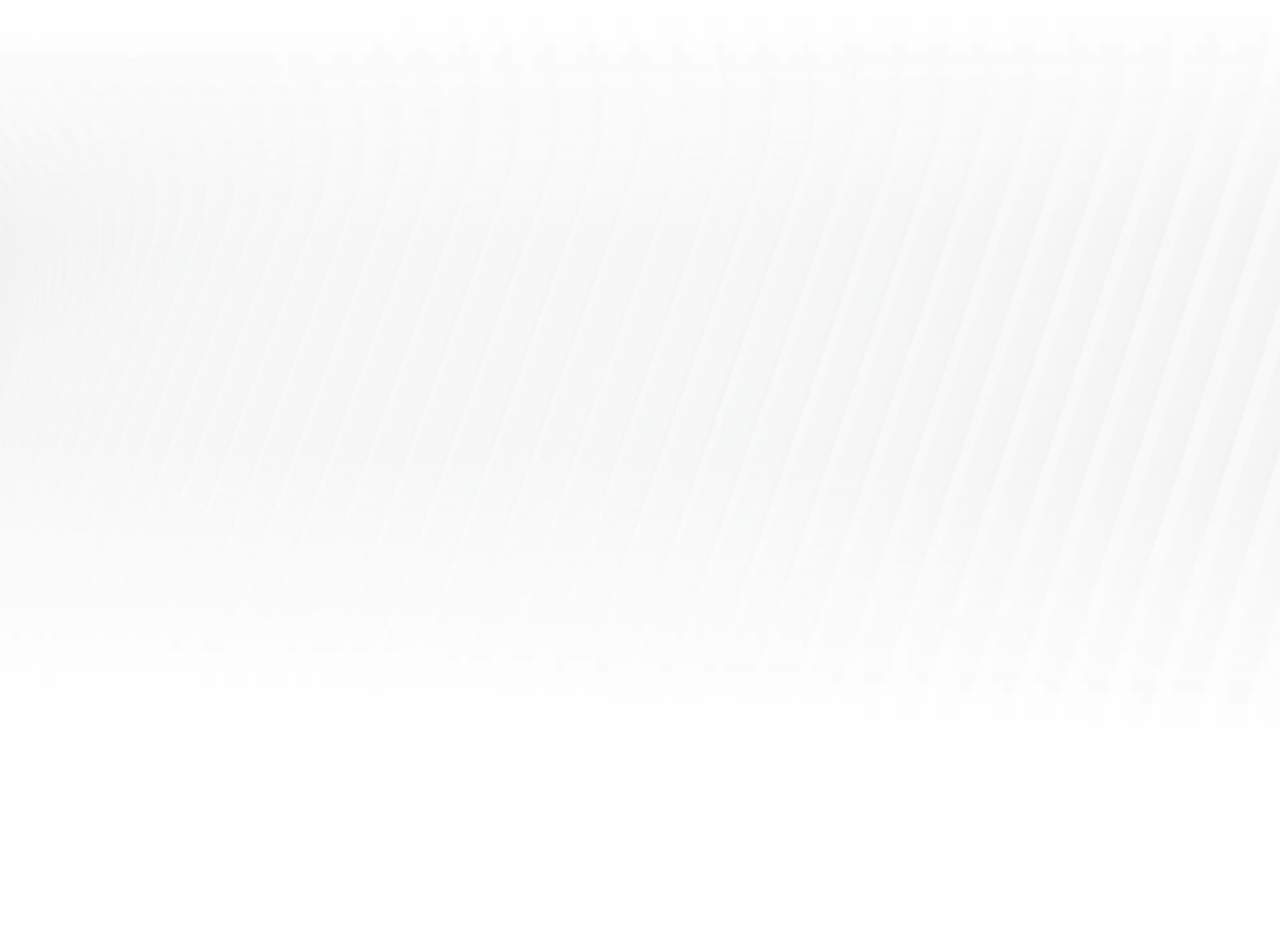

DuFLEX® Foam Panels are available with the complete Divinycell® structural foam core range:

Divinycell® H

Excellent stiffness-to-weight, good impact strength, low water absorption, reliable processing.

Divinycell® HP

Improved elevated-temperature stability, chemical resistance and mechanical efficiency in demanding environments.

Divinycell® HM

Exceptional stiffness density ratio for high-load structures; ideal where strength at minimal thickness is required.

Divinycell® PET

Recyclable thermoplastic core option; cost-effective, tough, lightweight and process-friendly.

These core materials offer outstanding mechanical performance, fatigue resistance, thermal stability and bonding characteristics — making them ideal for advanced composite structures in commercial marine, defence platforms, specialist vehicles, high-load industrial modules and architectural systems.

Applications Across Marine, Transport, Industrial & Defence

DuFLEX® Foam Panels are used extensively across structural and semi-structural composite builds, delivering lightweight efficiency, reliable performance and accelerated construction.

Typical applications include:

Hulls, decks, superstructures and internal modules

Bulkheads, frames, stringers and composite reinforcements

Road and rail walls, floors, doors, roofs and partitions

Specialist transport panels, truck bodies and high-load modules

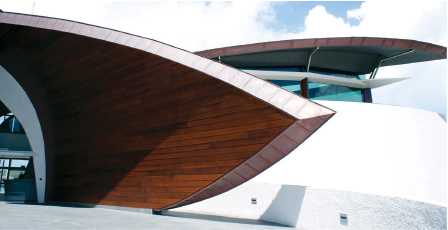

Long-span roofing, architectural cladding and façade systems

Industrial energy systems and infrastructure components

Defence vessels, mission modules and lightweight tactical platforms

Modular building systems, including prefab structural assemblies

Wet-area modules, shower pods and service cores

Structural vehicle flooring and wall systems for vans, trucks and service vehicles

From one-off custom builds to high-volume production, DuFLEX® delivers consistent quality, predictable structural performance and significant reductions in labour and build time.

Engineered for Strength, Efficiency & Speed of Construction

DuFLEX® significantly reduces the labour, waste and technical complexity associated with traditional hand-laminated composite structures. By eliminating multiple laminating, coring and full vacuum-bagging steps, DuFLEX® panels enable:

- Faster build times with cleaner fabrication

- Reduced material waste and tooling cost

- Controlled, repeatable laminate quality

- Improved strength, impact tolerance and fatigue performance

Every DuFLEX® panel can be engineered to suit the project — laminate schedule, fibre orientation, resin system, and core density can all be tailored to meet precise structural requirements including:

- Weight reduction targets

- High impact and slamming loads

- Span-driven stiffness demands

- Shock, vibration, fatigue and mechanical resilience

Panels are supplied with peel ply for a contamination-free bonding surface to accelerate secondary bonding and laminating.

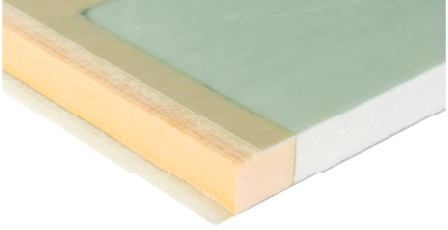

DuFLEX® panels can be supplied with precision-machined Z-Joints along the long edges to streamline installation. When bonded with a high-density epoxy adhesive, the Z-Joint provides:

Structural continuity

Smooth, fair surface transitions

Faster assembly with high alignment accuracy

This system behaves similarly to a weld in aluminum – modulus continuity is retained, ensuring stiffness performance across the joint.

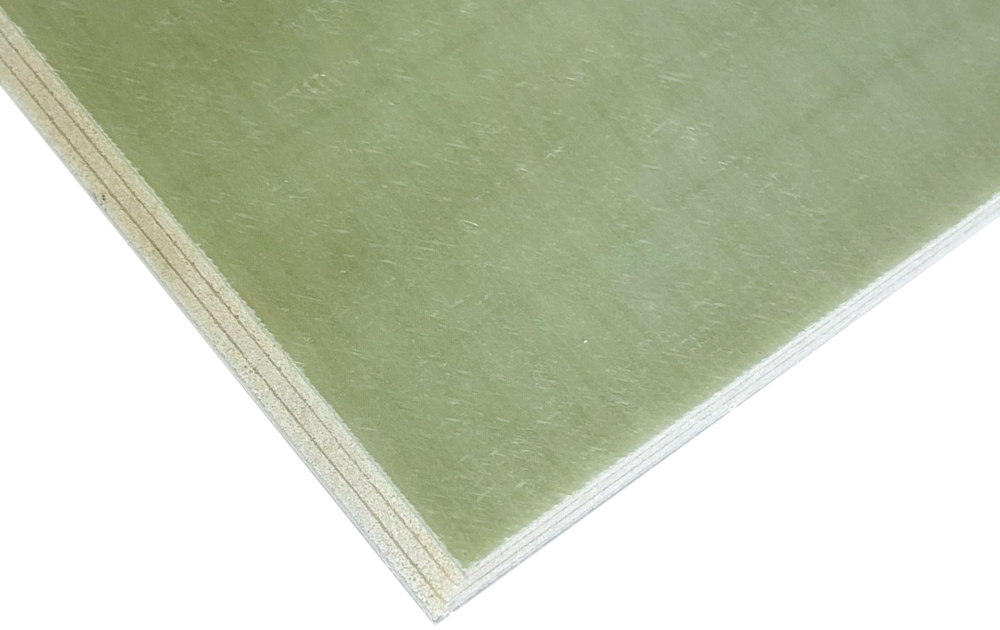

ATL Composites provides complete CAD-to-CNC service for streamlined production.

We engineer every panel to the requirements of your project:

Custom laminate schedules

Tailored fibre orientation

Optimised core density selection

Structural design for stiffness, weight, fatigue & impact

Supplied flat, curved, pre-cut or fully CNC-kitted

Send your drawings — we cut, label and prepare your full build kit for rapid, clean assembly.

Cutting, Finishing & Fabrication

DuFLEX® can be processed using standard composite tooling. For best results:

Use diamond-coated tools for edge quality and longevity

Aluminium-grade circular blades deliver clean cuts (with shorter life)

Peel ply enables fast, dust-free secondary bonding

Panels can be ripped, machined, drilled and edge-profiled with ease

DuFLEX® Panels can be supplied with calibrated hardwood veneers to create premium decorative surfaces ideal for:

• Marine cabinetry and luxury yacht interiors

• Architectural joinery

• Furniture and commercial fit-outs

• Interior modules and accommodation spaces

ATL also offers a wide selection of surface finishes to suit design, weight and performance requirements, including:

• Melamax laminates

• Laminex laminates

• Carbon, aramid and flax fibres