Why Builders Choose Full-Sized Components

1. Faster Build Speed

Components arrive pre-cut, pre-joined and fit-ready.

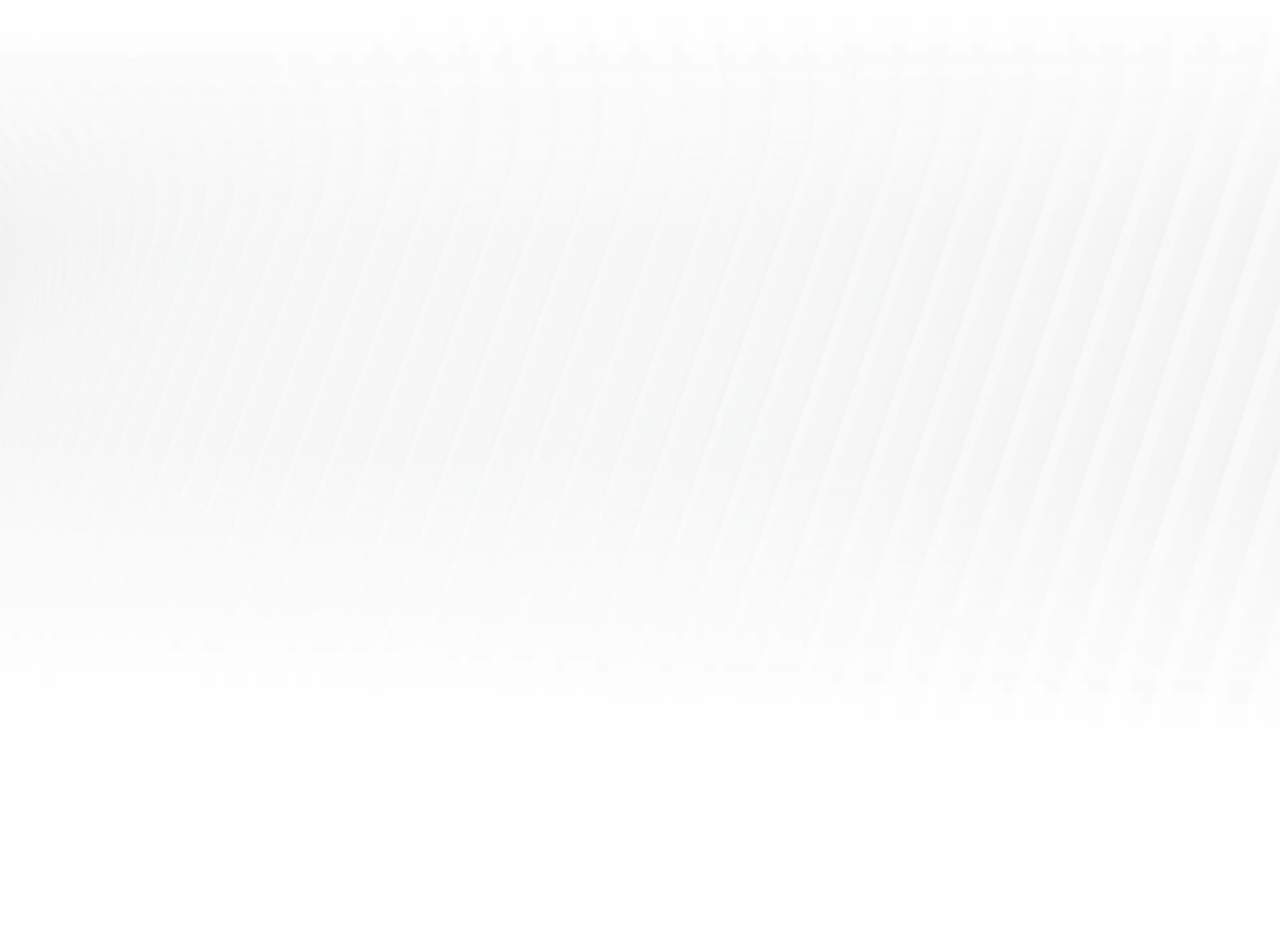

Builders simply position and tape them into place — no panel joining, no layout time, no trimming.

2. Reduced Labour & Workshop Waste

Precision nesting reduces off-cut waste.

Pre-joined parts eliminate fabrication steps and reduce the risk of errors.

3. High Dimensional Accuracy

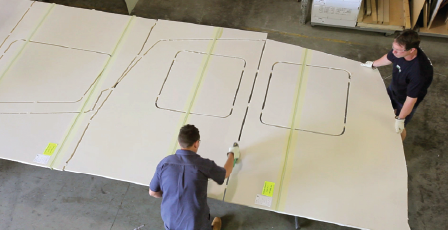

All parts are machined using state-of-the-art CNC routers for consistent, repeatable geometry.

4. Optimised for Modern Digital Workflows

Parts are produced directly from naval architecture or engineering CAD files, ensuring exact assembly fit.

5. Large, Complex Parts Made Easy

Curved, compound and multi-piece assemblies can be delivered as ready-to-use full panels.

6. Engineered for Marine & Industrial Loads

Suitable for primary and secondary structures in high-performance composite builds.

Advanced CNC Kitting Integration

Full-Sized Component Packs form part of ATL’s broader Precision CNC Kitting Services, which include:

-

High-accuracy nesting for DuFLEX®, Coosa® and Divinycell®

-

Digital flattening of curved surfaces

-

Micron-level machining precision

-

Component numbering and tabbing

-

Complete kit packaging for rapid assembly

-

Temporary frames available in plywood or MDF for alignment

-

ISO 9001:2015-certified processes

For projects requiring larger prefabricated parts, ATL can supply fully assembled component packs — reducing production time from weeks to days.

Full-Sized Components can be manufactured from:

DuFLEX® Structural Panels

Featherlight® Ultra-Light Panels

FRP Laminates

Coosa® Composites

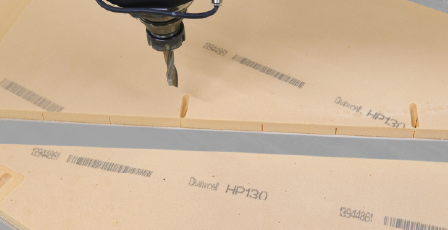

Divinycell® Foam Cores

Options include:

Square-edge or Z-Joint panels

CNC-machined cut-outs, rebates and detailing

Integrated inserts (PVC, PET, Coosa®, FRP)

Kerfed or curved assemblies

Interior module kits and furniture sets

Marine

Bulkheads, soles, floors and interior modules

Catamaran and monohull structural sets

Decks, superstructures and furniture kits

Transportation

Caravan and RV interiors

Rail and road panel systems

Fleet conversions and lightweight modules

Architectural & Industrial

Structural lightweight partitions

Complex composite modules

Prefabricated bonded assemblies

Full-Sized Components enable builders to:

Reduce fabrication time

Minimise workshop waste

Improve accuracy and repeatability

Achieve faster hull and module turnover

Lower labour costs and handling time

Deliver high-quality composite structures with confidence

ATL’s integrated system — combining DuFLEX®, Featherlight®, CNC kitting, Z-Joining and Full-Sized Components — provides one of the most efficient composite construction workflows available today.

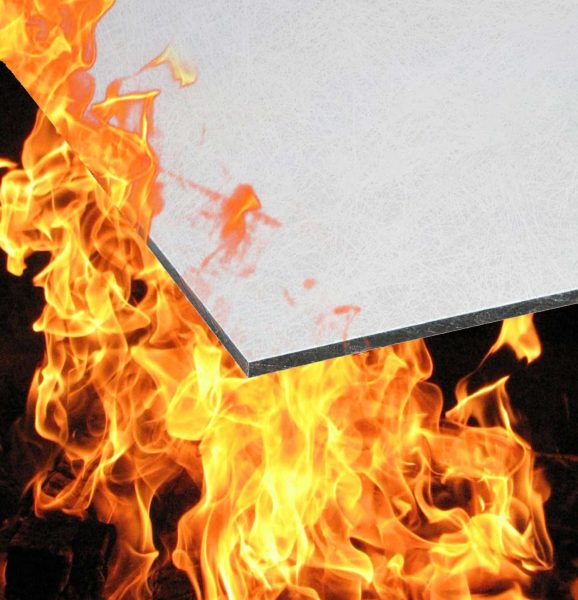

Installation & Secondary Bonding

Concerns sometimes arise regarding secondary bonding between different resin systems. Because DuFLEX® and Featherlight® panels have an inert cured surface, polyester, vinyl ester and epoxy resin systems can all be used to successfully bond Full-Sized Components into place.

Modified ISO 527 double lap joint testing demonstrated that polyester tabbing achieves the same strength on both polyester and epoxy substrates.

Lap Joint Test Results

| Specimen | Failure Load (kN) | Apparent Shear (MPa) | Failure Mode |

|---|---|---|---|

| A | 42.45 | 5.66 | Interlaminar Shear* |

| B | 48.47 | 6.46 | Interlaminar Shear |

| C | 46.50 | 6.20 | Interlaminar Shear |

| D | 47.08 | 6.28 | Interlaminar Shear |

* Interlaminar failure occurred within the CSM layer of the tabbing laminate.

** One specimen showed adhesive failure between tabbing and substrate.

Conclusion: Polyester tabbing performs equally well on both epoxy and polyester substrates — confirming reliable cross-compatibility for secondary bonding.