Work has begun on a wooden boat project uniting modern construction and traditional methods and aiming to showcase the enduring appeal and relevance of the Shipwright.

Work has begun on a wooden boat project uniting modern construction and traditional methods and aiming to showcase the enduring appeal and relevance of the Shipwright.

“The aim is to introduce a world class shipwright training program back into The Wooden Boat Centre,” said Paul D’Olier, Operations Manager.

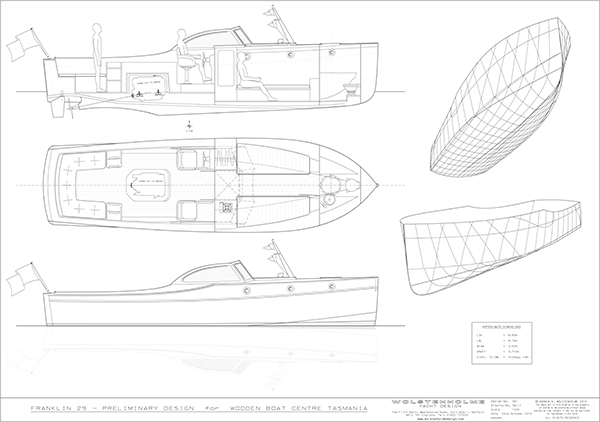

| LOA | 8.95 m |

| LWL | 8.76 m |

| Beam | 2.52 m |

| Draft | 0.71 m |

| Displacement | 4,100 kgs ( SW) |

| Cruise Speed | 17 knots |

| Engine | 100 hp low emission diesel |

| The Wooden Boat Centre | |

| Wolstenholme Yacht Design | www.wolstenholmedesign.com |

The Franklin 29 provides a heritage-looking boat that fits the image of The Wooden Boat Centre as a traditional boat builder, featuring a modern finish and low maintenance. The unique appeal of this vessel is the blend of traditional looks, modern convenience and beautiful Tasmanian timbers. It’s an excellent platform for the major portion of the new course, as it provides training opportunities in the full gamut of skills.

Disciplines involved will include modern construction strip plank methods including CNC cut moulds and bulkheads; introduction to modern adhesives and fillers used in strip plank construction; vacuum bag sheathing processes; Dynel deck sheathing; composite bulkhead materials; laid deck installation; interior fit out and mechanical and electrical fit out.

The Wooden Boat Centre will build in a variety of both traditional and modern boat construction methods as Course content needs to be consistent year on year. Traditional construction components were easy with our small clinker and carvel boats that are a staple for us.

ATL Composites, in conjunction with their local distributors Tasmanian Marine Distributors, have been working closely with The Wooden Boat Centre over the last couple of months, providing recommendations on materials and construction techniques for the Franklin 29 project.

The 29 will feature a strip-planked hull made from Western Red Cedar, laid decks of Celery Top Pine, Huon pine on the transom and fitout with other Tasmanian native timbers.

WEST SYSTEM 105 epoxy and 206 Slow hardener have been specified as the base system and in particular WEST SYSTEM 105 and 207 Special Clear hardener combination will be used for all clear timber finishes on the project. The 105/207 combination has an ultraviolet inhibiting additive that will ensure an exceptionally clear, moisture resistant, timber finish and improved UV protection.

A mix of WEST SYSTEM Fillers, each possessing unique handling and performance, have been recommended to The Wooden Boat Centre to alter the consistency of the WEST SYSTEM resin and hardener, including the 413 Microfibre Blend for structural bonding and scarfing and 411 Microsphere Blend for edge-gluing the timber planks and non-structural filleting and filling, as well as 417 Low Density Filler for the fairing system under the proposed dark blue hull.

KINETIX R246TX thixotropic laminating resin will be used to extend the working time for laminating the hull and larger areas of the Franklin. Mac Dalton, from ATL, will be supporting The Wooden Boat Centre with technical advice during this process, and also offering expert techniques for the construction for smaller parts, that are intended to be used for some basic training of the students, on vacuum bagging.

Construction has begun on the Franklin 29. The project is on track for delivery ahead of the 2021 Wooden Boat Festival, 5 to 8 February, where it will be on display.

As of mid-May, the temporary hull molds have been completed and set up on the strong back, stem laminates have been shaped and steamed and hul planking will be the next step.

More soon....

Click thumbnails to enlarge