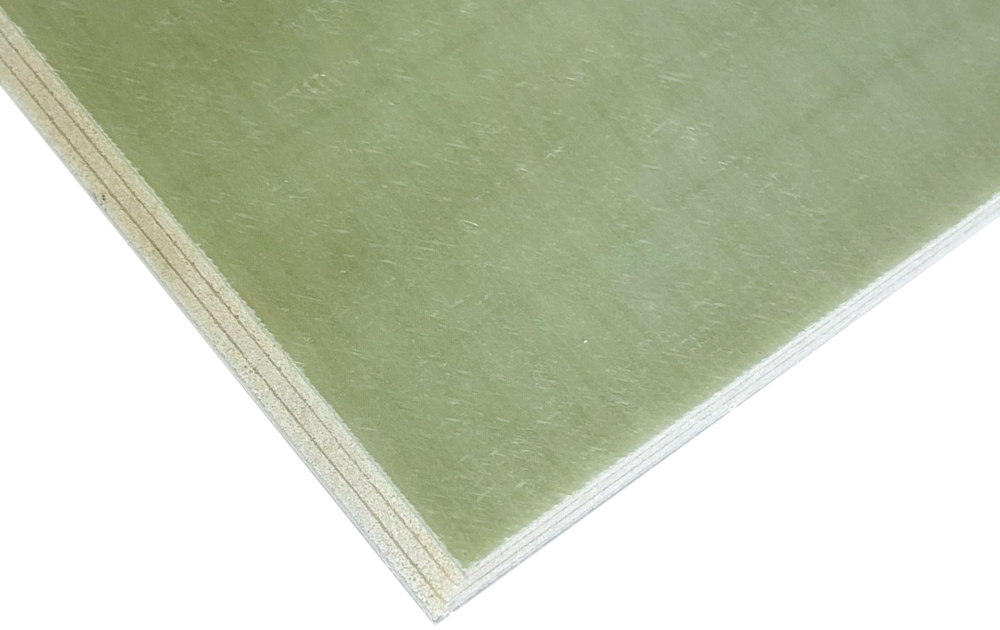

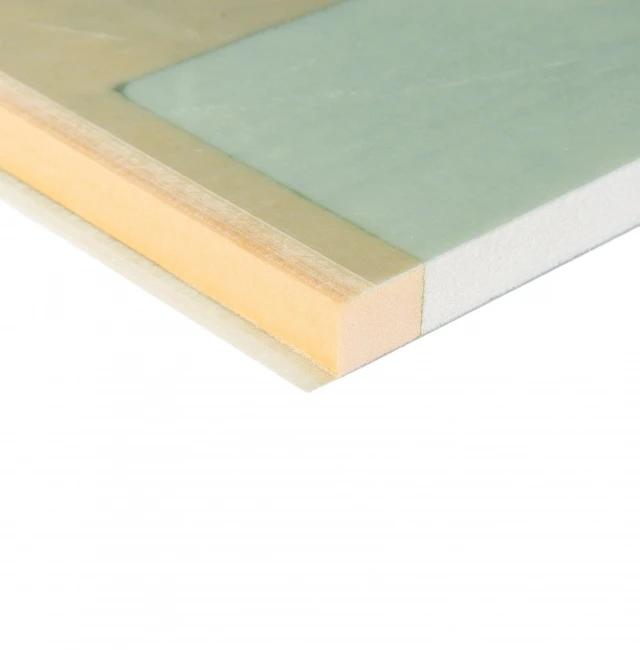

ATL Composites specialise in the design, formulation and manufacture of lightweight composite panel systems engineered for strength, efficiency and production speed. The DuFLEX® range offers high-performance panels manufactured with PVC or SAN foam cores, rigid end-grain balsa, aramid honeycomb, or COOSA® fibre-reinforced polyurethane board — providing structural solutions for yacht hulls and bulkheads, road and rail floors, truck bodies, industrial tanks and architectural long-span roofing.

For non-structural fabrication, Featherlight® panels provide an ultra-lightweight option for yacht interiors, furniture modules and architectural cladding, using low-density foams.

The panel range is further supported by DuraKore® strip planks, a modular strip-planking solution developed for custom marine construction, allowing builders to achieve fair, round-bilge hulls using a logical, sequential process.

All ATL composite panels are manufactured in a controlled production environment with rigorous quality assurance and traceability applied at every stage — ensuring consistency, reliability and repeatable performance.

– Smarter Materials. Stronger Outcomes