WEST SYSTEM SKIN PROTECTION + APPLICATION TOOLS

Disposable Static Mixers

Additional Static Mixing Nozzles Attachment for WEST SYSTEM® Six10 thickened epoxy adhesive.

| Pack Size | Sold in pairs. |

Reusable Mixing Sticks

A practical mixing, application, filleting and cleaning tool. Squared, beveled end reaches mixing pot corners for thorough mixing and blending in fillers and for cleaning up excess epoxy. Use rounded end to shape 3/8″ radius fillets. Cured epoxy pops of easily, so they can be reused many times. ¾”-wide x 5½”.

| Pack Size | 8 Pack |

| 60 Pack | |

| 100 Pack |

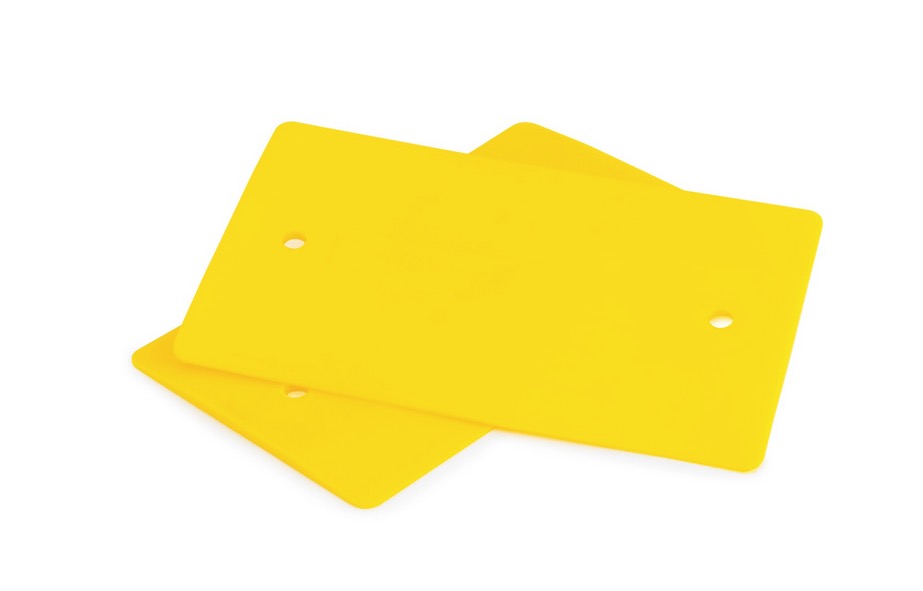

Flexible Plastic Squeegees

These versatile, reusable 12.7 x 152.4mm flexible plastic spreaders are designed for smooth, controlled application of epoxy systems. Featuring double-edged profiles, they are ideal for flow coating, fairing, filling, gap-filling and applying reinforcement fabrics. Their flexibility allows for precise material placement across flat or contoured surfaces, helping achieve clean, consistent results with every use.

| Pack Size | 2 Pack |

| 12 Pack |

Roller Frame

Durable roller frames designed to securely hold WEST SYSTEM® epoxy-safe roller covers. Narrow-cut covers provide improved reach and control when coating tight or confined areas, ensuring smooth, even film application every time.

| Pack Size | Sold individually |

Roller Cover

These thin polyurethane foam covers are the only roller covers recommended for epoxy application. The thin foam allows you to control film thickness, avoid drips and runs, and get a smoother coating. The 180mmcovers can be cut for smaller jobs, narrow strips and tight areas. Cut segments to make an ideal tipping brush.

| Pack Size | 2 Pack |

Mini Syringes

Reusable Syringes can be loaded with your epoxy mixture for injecting into tight spots. Ideal for hardware bonding and small repairs. Holds 12 ml 60cc.

| Pack Size | 2 Pack |

| 12 Pack |