Key Features & Benefits

Bluewater 20 is the most economical option in the Bluewater series, offering reliable long-term performance where weight and durability both matter.

THE COOSA ADVANTAGE

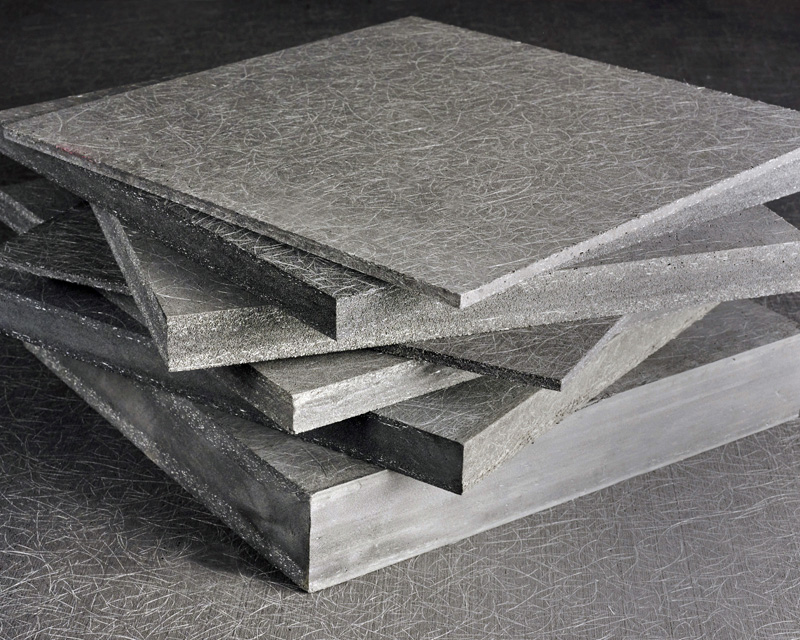

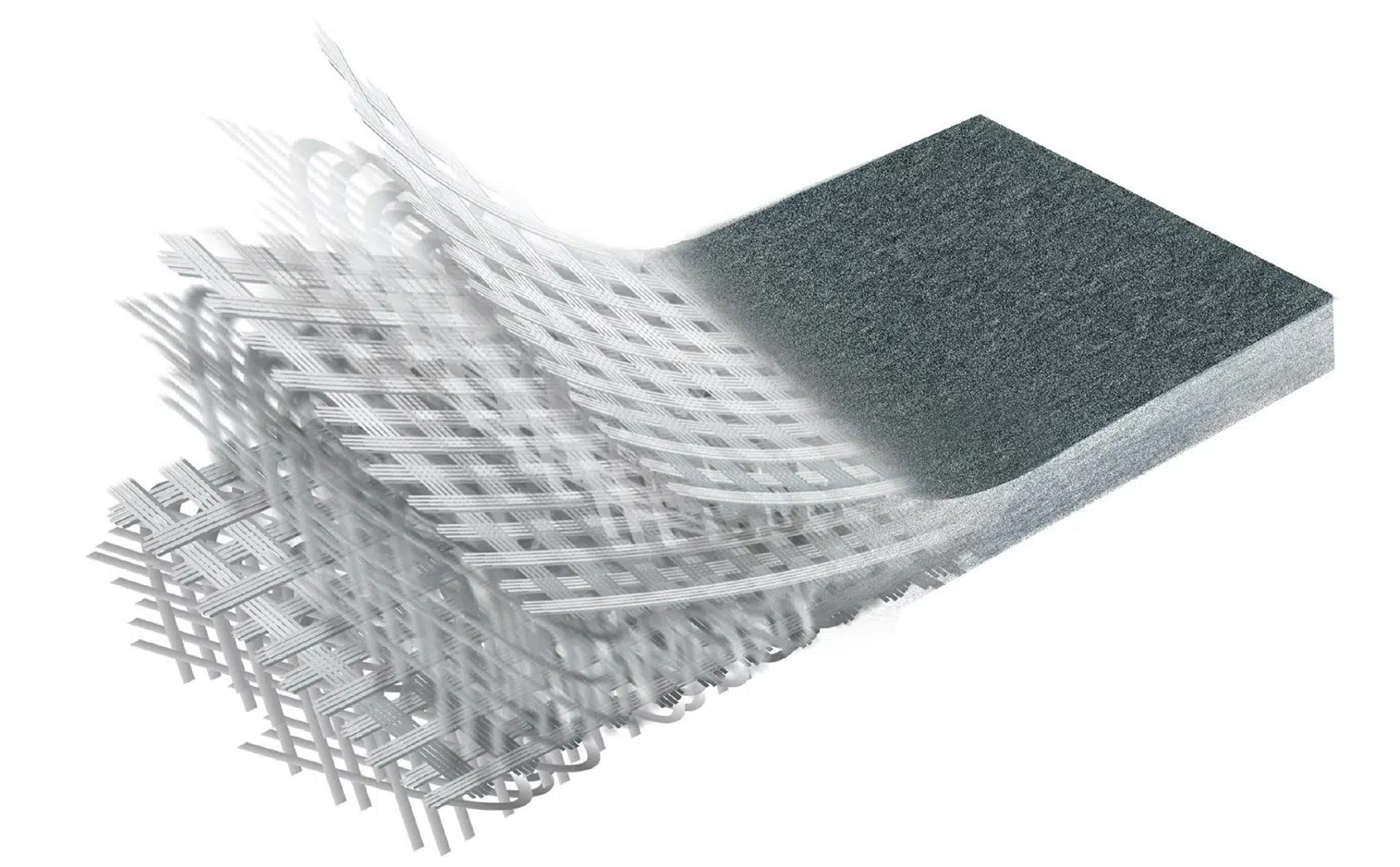

For more than 25 years, Coosa Composites has delivered advanced composite panel solutions trusted across marine, transport, industrial and recreational markets. Manufactured from high-density, closed-cell polyurethane foam reinforced with continuous-strand fibreglass, Coosa panels offer a strong, dependable alternative to plywood and other conventional core materials.

The fibre-reinforced structure delivers exceptional durability, impact resistance and long-term stability—performing reliably in harsh, wet or highly loaded environments where traditional materials often fail. This unique construction gives Coosa significant advantages over honeycomb, unreinforced foams, timber, and other sandwich core options, providing consistent performance, lighter weight and reduced maintenance for demanding composite builds.

Typical Applications

Transoms

Stringers and structural floors

Decks, hatch lids and bulkheads

Engine covers and other high-load structures

Floors for emergency vehicles, buses and specialised trucks

Sub-flooring and structural linings in trailers and coaches

Doors, bulkheads and heavy-duty interior modules

Exterior Cladding

High-load wall and floor panels

Equipment housings and trench covers

Structural elements in high-moisture or washdown areas

Supplied by ATL

ATL Composites offers complete supply, processing and engineering support for Coosa Bluewater 20, ensuring builders receive panels in the most efficient and project-ready format. Depending on project scale and requirements, ATL can provide:

Full Boards

Stocked in a range of thicknesses and ready for direct fabrication or lamination.Custom Pre-Cut Parts & Inserts

Precision-cut components tailored to your drawings, reducing labour time and ensuring accuracy for repeat builds.CNC Nested Kits

Optimised sheet layouts to maximise material yield, reduce waste and streamline installation. Kits arrive labelled and sequenced for efficient assembly.Integration within the DuFLEX® System

Bluewater 20 can be supplied as a core option within DuFLEX® composite panels for projects requiring laminated skins, engineered stiffness or large-format panel construction.

ATL accepts project files in DXF, DWG and PDF formats, enabling seamless CAD-to-CNC workflows and ensuring consistent, repeatable part quality for OEMs, commercial builders and custom fabricators.

COOSA MARKET APPLICATIONS

NO-ROT COMPOSITE PANELS FOR THE MARINE INDUSTRY

For 25 years, Coosa panels have been in the marine product market. The exposure to moisture a boat has to withstand (fresh and/or salt water) combined with the rigorous marine environment means only the best structural products will do. For boat construction or repair, Coosa is the premier product for replacing marine-grade plywood or other wood cores. With over 150,000 boats on the water containing Coosa’s marine boards, our materials have stood the test of time, exposure, and abuse.

Composite panel technology is transforming modern vehicle construction, delivering lighter, stronger, and more durable alternatives to traditional timber and standard sandwich cores. Coosa composite panels — manufactured from high-density, closed-cell polyurethane foam reinforced with continuous fibreglass — are engineered to meet the structural and environmental demands of commercial transport platforms. Offering excellent compressive and flexural strength, superior fastener retention, and complete resistance to water absorption, rot, and mould, Coosa is widely specified across buses, coaches, truck bodies, RVs, emergency vehicles, and service fleets for floors, walls, ceilings, bulkheads, and interior fit-outs. Compared to conventional materials, Coosa panels help reduce overall vehicle weight, improve fuel efficiency, lower maintenance requirements, minimise downtime, and extend asset service life, with fire-rated options further enhancing passenger safety and compliance in next-generation vehicle builds.

Recreational vehicle design has evolved rapidly in recent years, driven by the rise of off-grid travel, remote touring, and full-time nomadic lifestyles. Modern RV builds demand lighter structures for improved fuel efficiency, without compromising durability or long-term reliability in harsh environments. Coosa composite panels provide an advanced solution — manufactured from high-density, closed-cell polyurethane foam reinforced with continuous fibreglass, they function as both a structural core and integrated water barrier. This composite construction delivers exceptional strength-to-weight performance, resists water ingress, rot, and mould, and reduces ongoing maintenance requirements, making Coosa an ideal material choice for flooring, walls, cabinetry, and structural fit-outs across next-generation RV and motorhome platforms.

Composite panels are increasingly specified across architectural and infrastructure projects as designers seek lightweight, durable alternatives to traditional building materials. Coosa composite panels are engineered to meet demanding structural and environmental requirements, offering high strength-to-weight performance alongside complete resistance to water ingress, rot, and infestation, with excellent dimensional stability in both interior and exterior applications. Available in a range of densities to suit load and span requirements, Coosa panels provide a versatile solution for façades, fit-outs, joinery, and structural elements. Compared to plywood and conventional substrates, fibre-reinforced composite panels are easier to machine and install, accelerating construction timelines while reducing long-term maintenance and lifecycle costs — enabling architects and builders to deliver innovative, high-performance structures without compromising durability or budget control.

Coosa composite panels are engineered to meet the demanding performance requirements of industrial and commercial environments, delivering a durable alternative to traditional timber and standard core materials. Manufactured from high-density, fibreglass-reinforced polyurethane foam, Coosa panels provide exceptional resistance to water ingress, rot, and infestation while maintaining long-term dimensional stability across a range of densities to suit both structural and lightweight applications. In industrial settings where moisture, flooding, or harsh operating conditions are present, Coosa panels outperform conventional substrates by reducing maintenance, eliminating decomposition-related failure risks, and improving workplace safety by preventing warping and surface degradation. Their lighter weight also benefits overhead and mobile structures, while fire-rated options provide an added layer of protection where compliance and safety are critical — making Coosa a versatile solution across infrastructure, processing facilities, transportable buildings, and heavy-duty industrial fit-outs.

Coosa composite panels are engineered for specialised applications where conventional materials cannot meet structural or environmental demands. Manufactured from high-density, fibreglass-reinforced polyurethane foam, they deliver exceptional strength-to-weight performance with complete resistance to water ingress, rot, and corrosion. Ideal for marine refits, defence platforms, modular infrastructure, medical fit-outs, and mobile service units, Coosa panels provide a stable, machinable substrate capable of supporting high hardware loads while maintaining long-term dimensional integrity — offering a versatile composite solution for projects requiring enhanced durability and performance.

Contact the ATL Composites team to discuss your project requirements and specify the right Coosa panel solution.