Advanced Composites for a New Era of Automotive Performance

ATL Composites provides high-performance epoxy systems, structural adhesives, composite panels, and engineered cores that support innovation across the automotive, transport, caravan, rail, EV, and motorsport sectors. As manufacturers push for lighter vehicles, improved efficiency, and reduced emissions, composite technologies deliver the strength-to-weight performance, corrosion resistance, and design flexibility required for next-generation mobility.

Our locally developed materials support everything from high-volume production components to specialist and motorsport builds, improving durability, reducing assembly time, and enabling precision construction across a wide range of transport applications.

Composite Engineering for Automotive & Transport

ATL Composites works closely with engineers, fabricators, and manufacturers to address key automotive requirements, including:

Reducing vehicle and component weight

Improving fatigue life and durability

Increasing build speed and reducing labour

Enhancing thermal and dimensional stability

Replacing timber or steel with stronger, lighter alternatives

Whether bonding large curved caravan panels, producing stiff lightweight components for EV platforms, or manufacturing durable rail interiors, ATL materials deliver consistent, long-lasting performance.

Automotive Composite Systems

KINETIX® Epoxy Systems

KINETIX® epoxy infusion and laminating systems deliver excellent fibre wet-out, controlled exotherm, and high mechanical performance for precision automotive components. Ideal for structural laminates, underbody assemblies, EV battery enclosures, rail interiors, and lightweight body panels, these resins support efficient processing across infusion, RTM, and filament winding.

TECHNIGLUE® Structural Adhesives

TECHNIGLUE® adhesives provide high-strength bonding for composites, metals, cores, and hybrid structures. Engineered for sag resistance, gap filling, and long-term durability, they are trusted for bonding caravan walls and floors, truck bodies, trailer components, rail assemblies, and motorsport structures.

Duratec® Primers & Coatings

Duratec® in-mould coatings deliver smooth, paint-ready surfaces directly from the mould, reducing post-finishing and improving part quality. Suitable for exterior panels, interior trims, and decorative components, these coatings enhance appearance, durability, and production efficiency.

DuFLEX® Engineered Panels

DuFLEX® composite panels combine lightweight structural cores with high-performance epoxy laminates, providing fast, strong, and stable solutions for caravan floors, rail interiors, truck beds, cabinetry, and commercial transport builds. These panels reduce weight, labour, and installation time while improving durability and dimensional reliability.

COOSA® Composite Boards

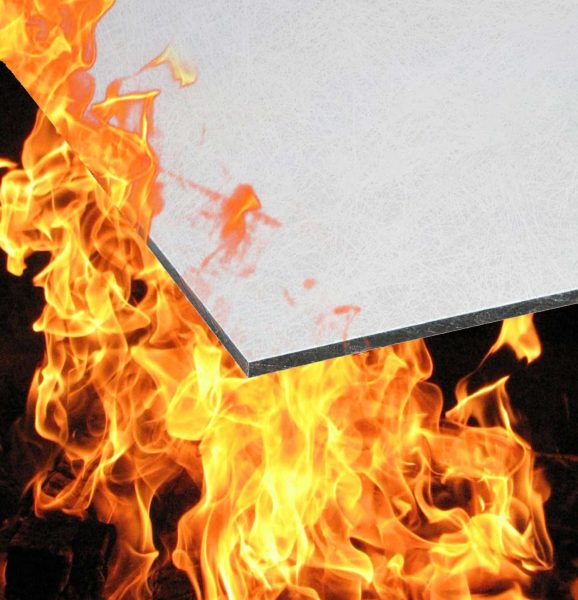

COOSA® high-density composite boards provide a lightweight, rot-proof and water-resistant alternative to plywood for automotive, transport and emergency-vehicle construction. Offering exceptional stiffness and durability under vibration, COOSA® is ideal for subfloors, walls, doors, roofs, partitions and reinforcement zones across trucks, trailers, buses and specialty vehicles. In fire trucks and ambulances, COOSA® delivers long-term structural stability, wash-down resistance and is available in fire-rated options for enhanced safety. Its strength-to-weight efficiency also makes it an excellent substrate for wheelchair-accessible and mobility-conversion vehicles, supporting reinforced floors, ramps and lift systems without absorbing moisture or degrading over time.

DIAB® Structural Foam Cores

DIAB® Divinycell® cores deliver excellent stiffness-to-weight performance, fatigue resistance, and thermal stability for infusion and RTM-processed automotive components. Used in lightweight panels, interior structures, EV platform components, rail fittings, and sandwich structures, DIAB® cores help manufacturers improve fuel efficiency, reduce emissions, and optimise component durability.

Performance That Drives Innovation

ATL Composites supplies advanced resin systems, adhesives, panels, and cores that help automotive and transport manufacturers build lighter, go further, and perform stronger — with reliable processing, long-term durability, and proven results across the road, track, and production line.