Advanced Composite Solutions for Defence and Sovereign Capability

ATL Composites is a trusted Australian manufacturer and formulator of advanced composite systems supporting the Defence, Maritime, Aerospace, and Land sectors. Backed by ISO 9001:2015, JOSCAR-AU registration, and DNV-certified processes, ATL delivers true sovereign capability through complete control of resin formulation, panel engineering, adhesive technology, and system integration — all performed at our Australian manufacturing facilities.

Our composite systems — including DuFLEX® engineered panels, KINETIX® and WEST SYSTEM® epoxies, TECHNIGLUE® structural adhesives, COOSA® reinforcement boards, and DIAB Divinycell® cores — are used across patrol vessels, UAVs, UUVs, and autonomous ground systems. Engineered for strength, corrosion resistance, lightweight efficiency, and long-term durability, ATL materials deliver reliable performance in the harshest operational environments.

ATL’s composite technologies are formulated to meet the specific requirements of defence and aerospace applications, offering:

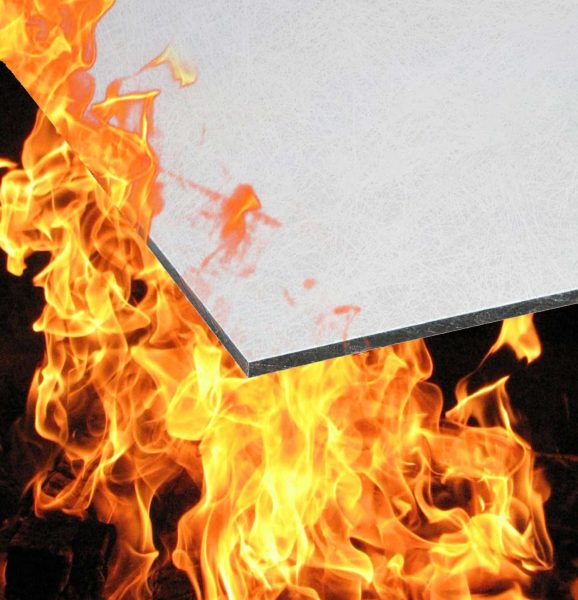

High-temperature stability for thermal load environments.

Fire performance for increased safety and survivability.

Electrical insulation for systems integration and signature management.

Water and chemical resistance for marine and underwater operations.

Low-temperature capability for cryogenic, aerospace, and arctic conditions.

With in-house chemists, engineers, and fabricators, ATL collaborates with defence primes and OEMs to develop tailored material solutions that enhance platform efficiency, stealth, and operational endurance. Local production ensures secure supply chains, assured quality, and consistent availability of mission-critical materials.

Defence Innovation Built on Australian Capability

ATL Composites advances Australia’s defence advantage through continuous material innovation. From formulated epoxy systems and structural adhesives to integrated panel and core technologies, every ATL product is engineered to deliver lighter, stronger, and more resilient platforms across sea, land, air, and unmanned systems.

Our sovereign manufacturing base, certified quality systems, and collaborative engineering approach allow defence partners to accelerate capability development, reduce weight, and improve durability — strengthening Australia’s long-term strategic readiness.

Product Systems for Defence Platforms

KINETIX® delivers aerospace-grade consistency and structural performance in mission-critical composite components. With excellent fibre wet-out, low exotherm, and high mechanical strength, these resins are ideal for UAV fuselages, radomes, rocket structures, and naval components. Suitable for hand layup, infusion, RTM, and filament winding, KINETIX® provides predictable processing and thermal stability from prototype to deployment.

TECHNIGLUE® adhesives provide high-strength bonding of composites, metals, and core materials in defence applications. Offering superior gap-filling, sag resistance, and long-term durability, they perform reliably under vibration, impact, and high loads. Used in drone assemblies, hull-to-deck joins, bulkheads, and payload structures, TECHNIGLUE® ensures precise, secure, and resilient bonding performance.

Duratec® in-mould primers and coatings deliver a high-gloss, cosmetically finished surface directly from the tool, reducing post-processing and improving dimensional consistency. Suitable for radomes, fairings, interior panels and unmanned system enclosures, Duratec® enhances surface durability, UV stability and cosmetic quality across aerospace and defence components.

DuFLEX® panels combine high-strength epoxy skins with engineered cores to create lightweight, stiff, and impact-resistant structures. Used in UAV wings, control bays, superstructures, vehicles, and bulkheads, DuFLEX® reduces build time, improves weight accuracy, and ensures repeatability through CNC-machined precision. These panels form the structural foundation of modern defence platforms.

COOSA® composite boards offer high stiffness and impact resistance for naval, aerospace and land-based systems. Designed for structural durability and moisture resistance, they maintain dimensional stability in demanding environments. Common applications include reinforcement structures, decks, transoms, UAV frames and mounting interfaces.

Divinycell® foam cores deliver excellent stiffness-to-weight performance, vibration dampening, and fatigue resistance. Used in hulls, decks, bulkheads, radomes, and UAV structures, these closed-cell cores offer superior slamming performance and naturally low radar reflectivity — supporting signature-sensitive defence applications.

ATL Composites delivers Australian-made advanced composite materials for Defence, Maritime, Aerospace, and Land applications. Backed by ISO and DNV certification, ATL provides sovereign manufacturing capability and mission-ready epoxy, adhesive, and panel systems engineered for strength, durability, and operational performance in extreme defence environments.

Defence Capabilities

ATL Composites supports Defence capability through certified, locally manufactured composite systems designed for platform performance and operational readiness. With over 45 years of material science expertise, ATL delivers reliable epoxy, adhesive, core, and panel technologies that meet demanding defence requirements across air, sea, land, and unmanned systems.

-

SOVEREIGN MANUFACTURING CAPABILITY Local formulation, production, and engineering of epoxy systems, panel technologies, and structural adhesives — strengthening Australia’s defence supply chain.

-

CERTIFIED PRODUCTION SYSTEMS ISO 9001 and DNV-certified processes ensuring traceability, compliance, and repeatable performance in mission-critical applications.

-

TECHNICAL EXPERTISE In-house chemists, engineers, and composite specialists developing tailored materials and laminate systems for defence-grade use.

-

TAILORED SOLUTIONS AND PROVEN PERFORMANCE Materials proven across patrol vessels, autonomous systems, high-speed craft, and research programs, supported by ongoing sustainment, training, and technical assistance.

-

SECURITY AND CONFIDENTIALITY Strict management of controlled materials and sensitive projects under defence security and compliance frameworks.