Carbon Fibre Reinforcement Types

Carbon UD fabrics and tapes concentrate fibres in one direction, providing maximum tensile and compressive performance along a single axis. Ideal for:

Beam caps and stringers

Spars and masts

High-load structural reinforcements

Local stiffening and directional load paths

ZU300 / 5

300 g/m² Carbon Unidirectional “Thermoplastic” – 12K

Width: 500 mm

Roll Length: 100 LM

Provides extreme directional stiffness and strength with clean handling and efficient lay-up.

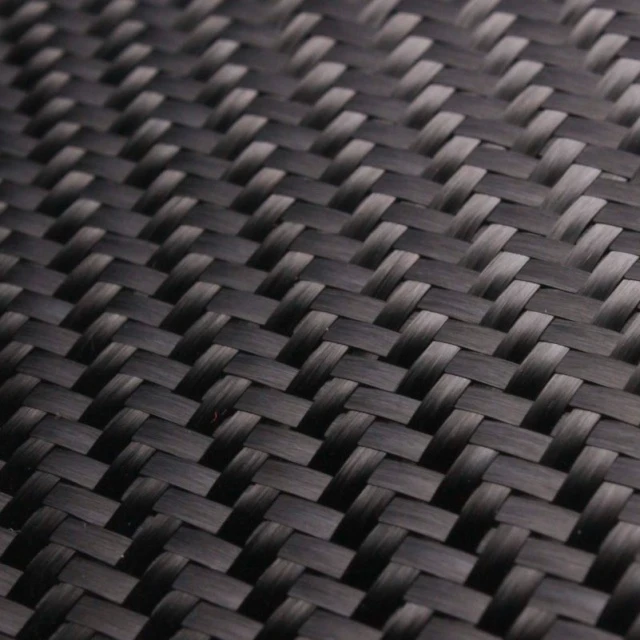

Plain weave fabrics use a simple over-under pattern, providing equal strength in both surface directions and excellent stability during lamination. Ideal for:

Large flat surfaces

Cosmetic surfaces

Skins for panels and mouldings

General composite laminating

ZP200

200 g/m² Carbon Plain Weave – 3K

Width: 1270 mm

Roll Length: 92.4 LM

Offers balanced mechanical performance and a clean woven appearance.

Twill fabrics use a 2×2 or similar pattern, producing a signature diagonal texture. This weave has superior drape and formability, making it the preferred option for curved geometry and visible carbon structures.

Benefits include:

Excellent drapability for complex curves

Improved cosmetic finish

Reduced bridging and air entrapment

ZW200

200 g/m² Carbon 2×2 Twill – 3K

Width: 1270 mm

Roll Length: 92.4 LM

Ideal for surfaces requiring high aesthetics and smooth draping around contours.

Carbon Double Bias fabrics consist of two stitched layers oriented at +45° and –45°, providing exceptional shear, torsional and twisting resistance. Ideal where:

Complex contours require flexible drapability

Laminates are exposed to torsional loads

Reinforcement is needed in non-axial directions

Curved hull sectors or composite tubes are being laminated

ZX300

300 g/m² Carbon Double Bias (+/–45°)

Width: 1270 mm

Roll Length: 100 LM

ZX400

400 g/m² Carbon Double Bias (+/–45°)

Width: 1270 mm

Roll Length: 100 LM

Both deliver high shear capacity and improved stability in long, narrow laminates.

Designed for ATL’s Composite Ecosystem

ATL carbon reinforcements are fully compatible with:

Kinetix® laminating epoxies

Techniglue® structural adhesives

DuFLEX® and Featherlight® composite panels

Polyester, vinyl ester and polyurethane resin systems

Ensuring superior wet-out, reliable mechanical performance and long-term structural durability across ATL’s composite systems.